We offer the advantage of NACE International and/or API certified engineers, scientists and technologists at an advanced level to address almost every type of corrosion, materials or pressure equipment integrity problem you are likely to encounter.

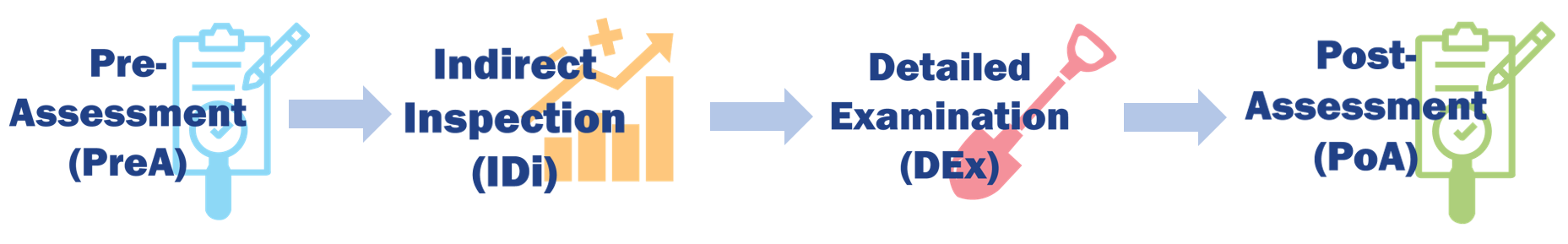

Internal Corrosion Direct Assessment (ICDA)

We offer a state-of-the-art, proprietary modeling solution ![]() for use in ICDA for prediction of corrosion rates within oil and gas pipelines. We strictly adhere to NACE International Direct Assessment protocols to ensure you get reliable, accurate results.

for use in ICDA for prediction of corrosion rates within oil and gas pipelines. We strictly adhere to NACE International Direct Assessment protocols to ensure you get reliable, accurate results.

Using this mechanistic model, we can help prevent pipeline failures before they happen. Using internal flow predictive modeling and solids deposition predictive modeling, we provide a better understanding of the corrosion environment and flow-behaviour within your system.

Features:

Slug flow model from in-house modelling software

- Reliable internal pipeline corrosion prediction with

to assist with wet gas, dry gas, multiphase and liquid petroleum ICDA practices

to assist with wet gas, dry gas, multiphase and liquid petroleum ICDA practices - Solids deposition and accumulation modeling for maintenance pigging optimization

- Corrosion inhibitor evaluations utilizing advanced testing protocols

- Oilfield water and hydrocarbon chemical analyses

- State-of-the-art corrosion rate detection and monitoring solutions

- Chemical corrosion inhibitor fingerprinting quality verification

- Real-time, on-line electrochemical corrosion surveillance protocol design

- Extensive sour service pipelines and plant process applications expertise

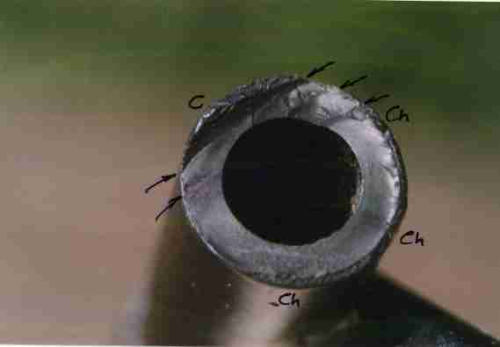

Failure Analysis

3D model of failure Disclaimer: 3D modelling of failures not done in-house

From our modelling and on-site inspections, we can help you determine the root cause of the failure, mechanical or chemical, and suggest preventative measures to prevent future failures from occurring again. Metallurgical investigation, coupled with a solid understanding of inorganic- and electro-chemistry, corrosion engineering, fluid hydrodynamics and mass-transfer effects converge to provide a definitive answer to most corrosion problems encountered in petroleum and other energy production operations.

Examples of our methods of root-cause determination are:

Materials Evaluation

- Materials specification – metallic and non-metallic

- Positive Material Identification (PMI)

- Mineral scale susceptibility and mixed-water compatibility assessment

Product and Asset Assessments

- Process and facilities design-basis corrosion review and input

- In-service and new equipment project corrosion risk assessment and mitigation design

Close-up of broken nylon fuel pipe connector caused by SCC – Peterlewis at en.wikipedia [Public domain], from Wikimedia Commons

- Corrosion engineering due-diligence audits/surveys of potential acquisition or divestiture properties for buyers or sellers BEFORE the deal is signed

- Pressure equipment fabricator/fabrication and installation auditing

- Advanced state-of-the-art comprehensive materials and inhibitor corrosion testing

External Corrosion Assessment

- Coatings, paint and linings evaluation, testing and selection

- Cathodic protection (CP) feasibility and performance evaluations

- Cracking susceptibility and environmental assessment

Microbiologically Influenced Corrosion (MIC) Analysis

Competent and experienced staff can consult on and assess the MIC risk in your system.

Services include:

- Advise on the best in-field or in-lab tests to provide meaningful data for your system

- Provide professional interpretation of NACE Certified MIC assays to give useful results

- Perform field trips to conduct MIC testing

- MIC failure analysis

- Assessment – Determine MIC risk within your system

- Assays – Capable of performing in-field microbial assays and in-lab testing

- Serial dilution bug bottles

- Biological Activity Reaction Test (BART) Bottles

- ATP assays

- DNA based sequencing

- Remediation – Suggest customized treatment regimens to control MIC in your system